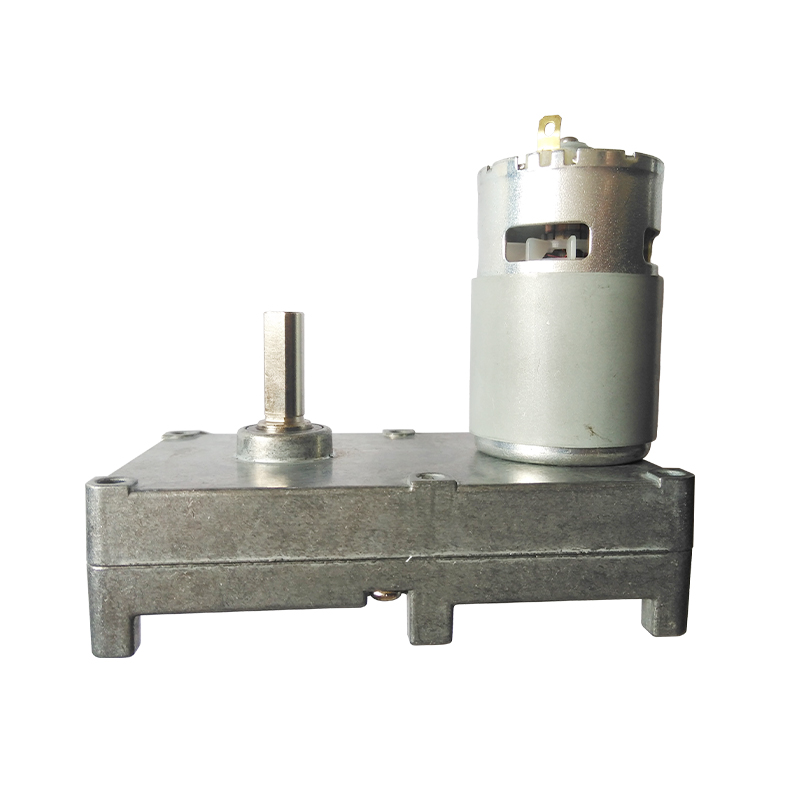

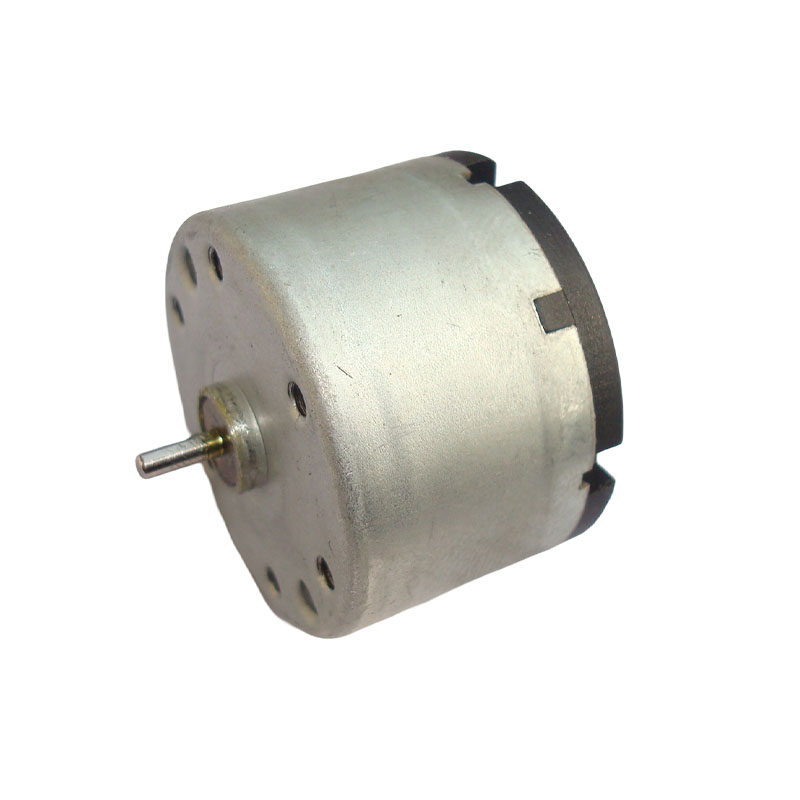

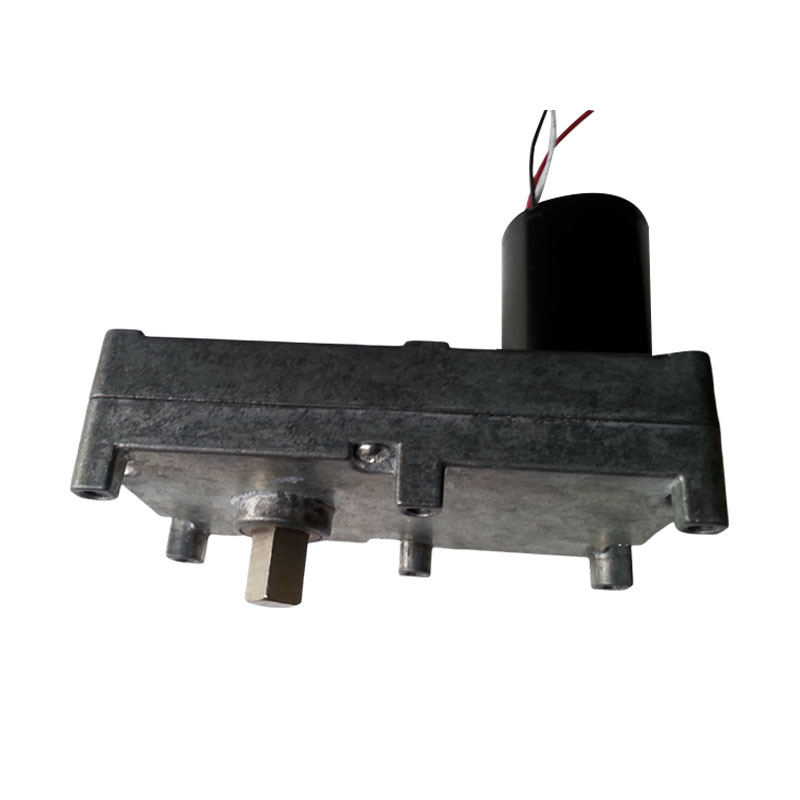

For the miniature gear motors that drive IC card reading/writing mechanisms, valve opening/closing, or mechanical counter resets, their "low-noise" characteristic is far from a bonus in these scenarios; it is a key design element concerning user experienc

- +86-18858098519

- 616594316@qq.com

- No. 17, Shenjiao Industrial Zone, Gulin Town, Haishu District, Ningbo